Frankland Racing - Quick Change Rear End

The Torino that I traded for the Tribute build came equipped with a stock 9" Ford rear differential (shown below). This rear end would have probably been adequate for what I am going to do with the car, but Punky had a quick change rear end in his Torino, and I want to match it as close as possible.

Back in 1947, Jim Frankland designed a rear end for racing that would allow a way for the racer to quickly adapt the gear ratio to match the conditions of the track. Thus Frankland Racing Supply was born.

All that was required to change the gear ratio was to remove 6 bolts from the back cover and swap gear sets. It also required draining and refilling a small amount of gear lube which is separate from the main reservoir.

Many dirt track racers in the 1970's (including Punky) were using these rear end differentials in the Late Model class.

I kept my eyes open and found a few quick changes online that might have worked. The price range was from $2000 - $3000 for a new one, to $500-$800 for a used unit. I was out on FaceBook a while back and someone posted an image of a Frankland that they were looking to sell. He said he would let it go for $250 and I jumped at the chance to go pick it up.

Back in May of 2018 I ended up driving down to Springfield, MO to pick up the Frankland. Apparently it had been used in a sprint car, so the center section had been offset to the left quite a bit.

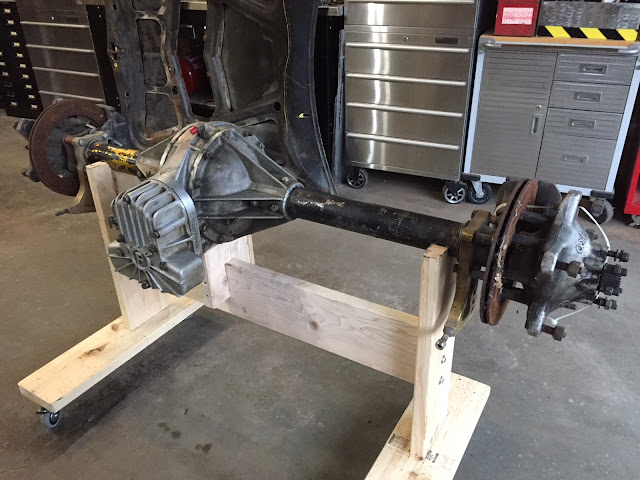

The first thing I did was to build a stand to hold the rear end while I tore it down.

Then I soda blasted the center section.

Next up, fitting and installation of symmetrical length axle tubes, and replacement of all hardware to grade 8 fasteners.

For a few different reasons, I decided to pick up a donor rear end to get the required Ford 4-link mounting brackets to transplant onto the quick change. The main reason is that I don't have the race car at my shop yet. A second reason is that I thought that it might be a good idea to have an additional rear end around in case something breaks in the future.

So I went out to the "local" restoration auto yard and picked up a 1972 Mercury Montego 9" housing.

Then went through the fairly complex process of cutting off all brackets (after building a jig to hold them in their factory locations), and then welding them onto the quick change.

The Frankland Quick Change is now almost ready to install in the Torino Tribute. I still need to purchase new Spohn brand upper and lower control arms ($450.00), cut-to-length axles with pressed on bearings ($300), rear disc brake conversion kit ($280), and a few other additional parts.

My next little project is to get the final exterior body panels ready for replacement. Take care until next time!